spresto9 wrote:This helped me! good luck...

What amazed me about that video was that his fingers didn't seem to be covered with scars! Just frightening!

ed wrote:nice description

is it as straightforward to put the chip back?

If you used VERY FINE enamelled wire, then the pins on the xFQP are not bent up much - note these pins break easily if bent too much... The Atmel chip is in a TQFP 100 package which has a pin pitch of only 0.5mm - pins & tracks on the PCB must be treated with respect.

With the removed chip, GENTLY press each edge in tun on a flat hard surface to align the pins and get them straight again. Clean the chip & pins with IPA - be very careful if using a cotton bud here as if a bit of cotton snags a pin, the pin can break...

So, now you have a clean chip and clean board. Using a flux pen, just wipe the pads gently with a tiny amount of flux (shouldn't need much - both pads & chip pins are already tinned)...

Align the chip ever so carefully over the pads making absolutely sure that pin 1 is in the right place - easy mistake to make with a square chip!

Tack a pin in one corner VERY CAREFULLY - re-tack until the chip seems well aligned on all 4 sides. Then tack a pin in the diametrically opposite corner. The chip should now be correctly lined up over the pads...

Using FINE (22AWG or similar) solder, preferably not with any extra flux in it (i.e. not Ersin muti-core etc.) just run the solder and the iron down each side in turn. Don't overload the pins or spend too long in any one area - also, don't worry about bridges between pins at this stage - we'll deal with that in a minute. The important thing here is that each pin is soldered to the pad beneath it, not how pretty the job is!

You now need a reel of fine solder wick - I use Chemtronics "Chem-Wik" with a size between 1 & 2mm, but any decent fine wick will do.

Lay the end of the wick along the whole of one side of the chip, over the newly soldered pins. Then starting at the end of the wick attached to the spool, press the soldering iron onto the top of the wick until you see some solder being absorbed (a few seconds) - slowly move the soldering iron down the row, gently lifting the wick off (whilst the solder in it is still molten so it doesn't stick to the pins) as its work is done. If the wick "sticks" to the pins - re-heat it gently - do NOT pull it as the pins may well break or a pad on the PCB may lift...

Miraculously (!!) as the wick lifts, you will be left with a perfectly soldered, clean, bridge & splash-free, row of pins. Repeat for the other sides. Note that if you really piled on the solder, you might need to repeat the wicking for a given side as fine wick doesn't absorb a huge amount of excess solder!!

Inspect very carefully with USB 'scope, magnifying light etc. Clean with IPA & cotton buds. Inspect again !

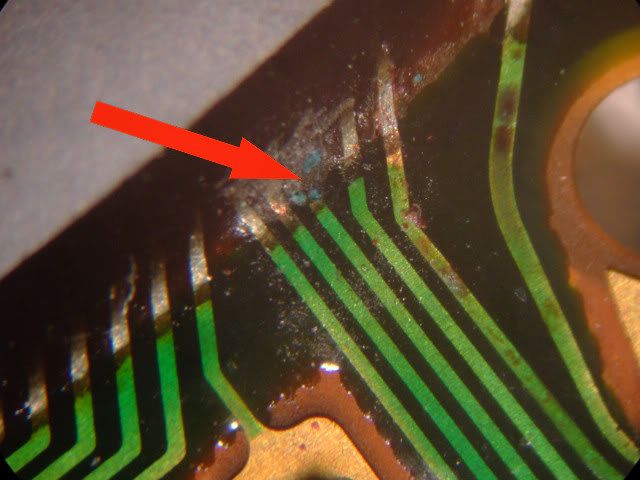

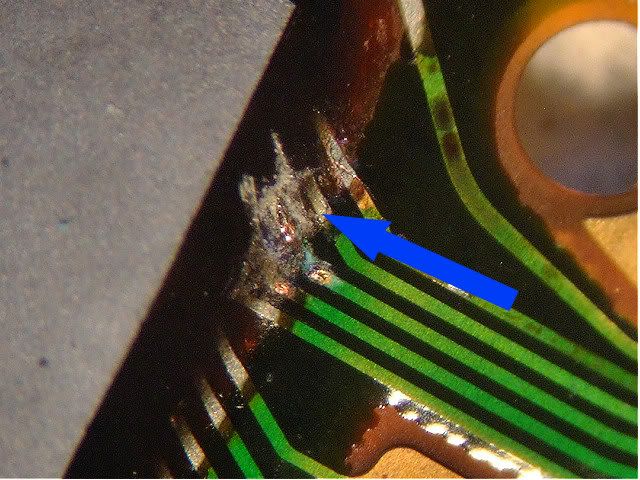

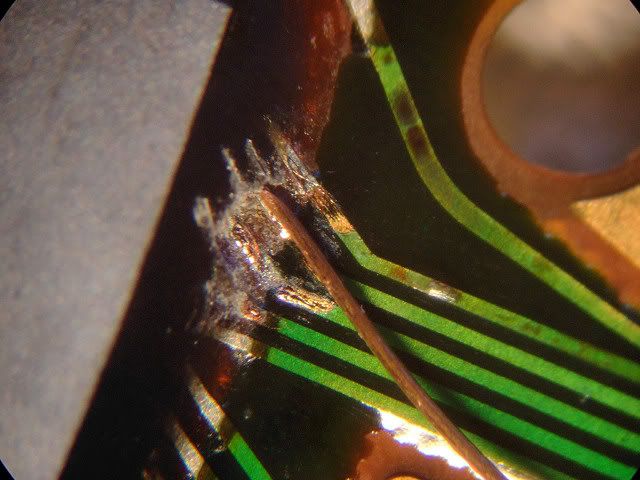

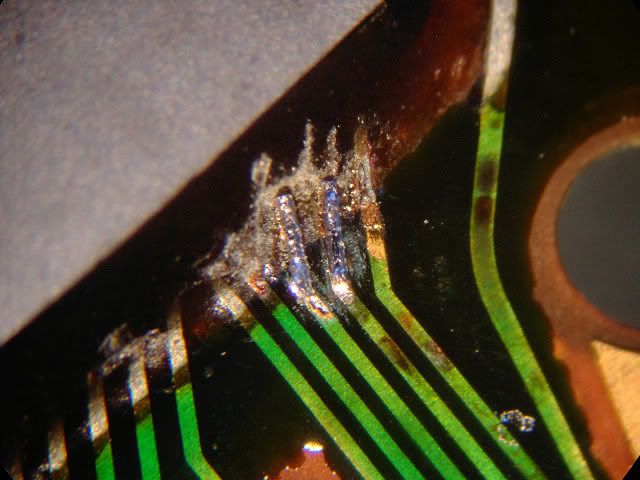

The photo in my previous post shows how the pins look after wicking.

Note these two techniques work for pretty much any non-BGA, i.e. leaded, SMD device.

No disrespect to Amanero, but that board is ROUGH!

EDIT: Use IPA in a WELL VENTILATED AREA only - IPA fumes can (do) give you a blinding headache - really nasty - happened to me once - just like someone was smacking the front of my head HARD every few seconds with a shot-filled cosh... very unpleasant...

HTH