A unipivot made from scrap

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#16 Re: A unipivot made from scrap

Blank now trued up, it will spin without wobble so can move on to the next stage. Note the cut made to mark the length of the finished piece. This is where I will part it off later

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#17 Re: A unipivot made from scrap

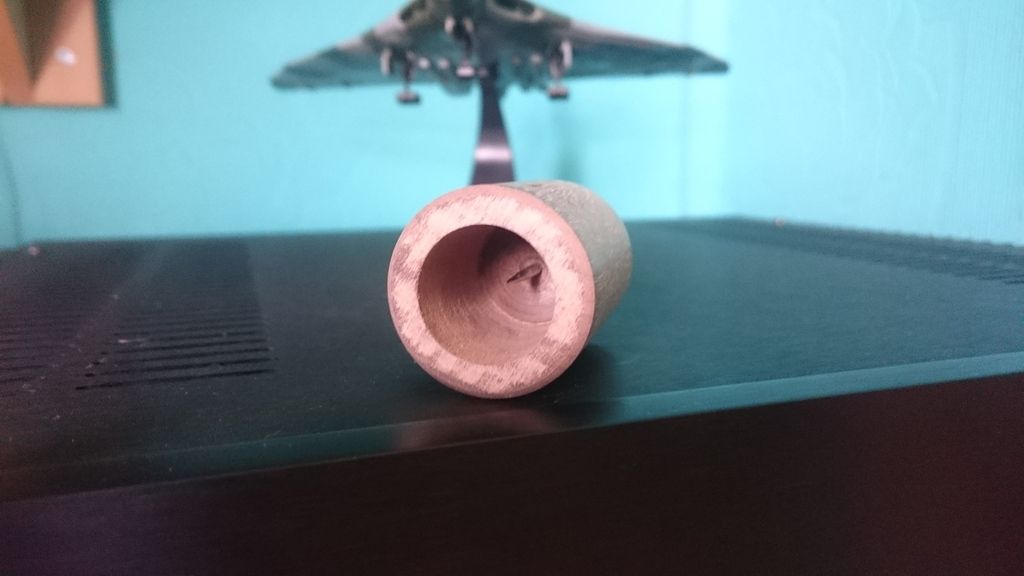

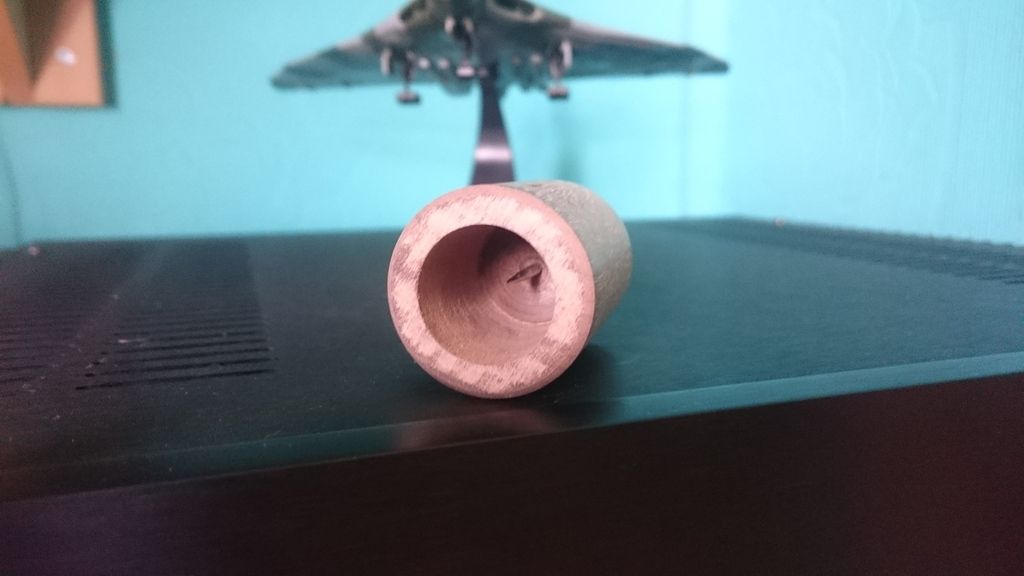

Next we fit a chuck into the tailstock. There are 2 operations, firstly a 2 mm hole which serves 2 purposes. This hole will go all the way through to where the piece will be parted off and form the hole that the pin will go into.

Secondly it will serve as a pilot for the second operation to hollow it out.

Ive used a 19mm forstner bit in the tailstock and used the advance to make it deep enough

Secondly it will serve as a pilot for the second operation to hollow it out.

Ive used a 19mm forstner bit in the tailstock and used the advance to make it deep enough

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#18 Re: A unipivot made from scrap

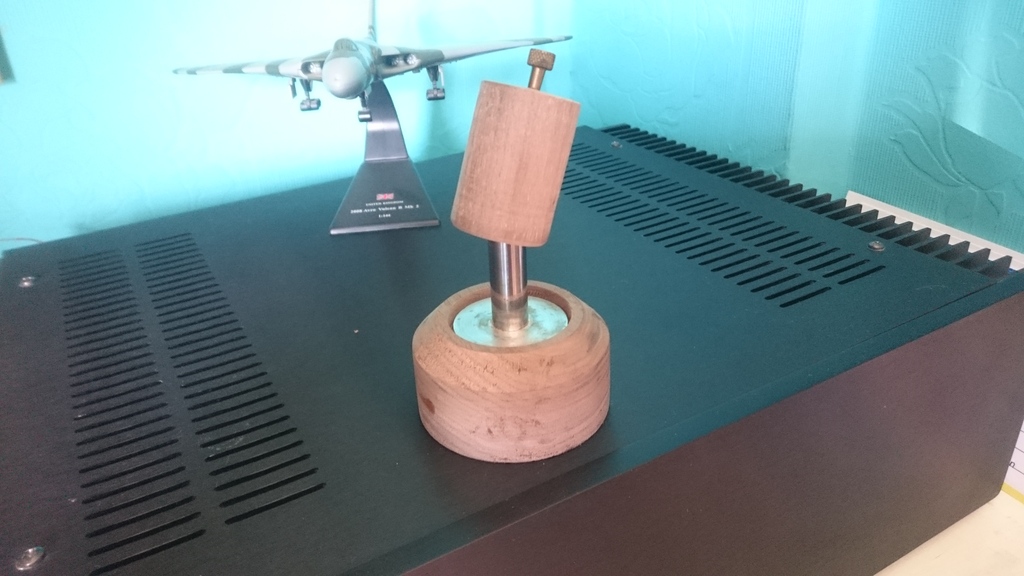

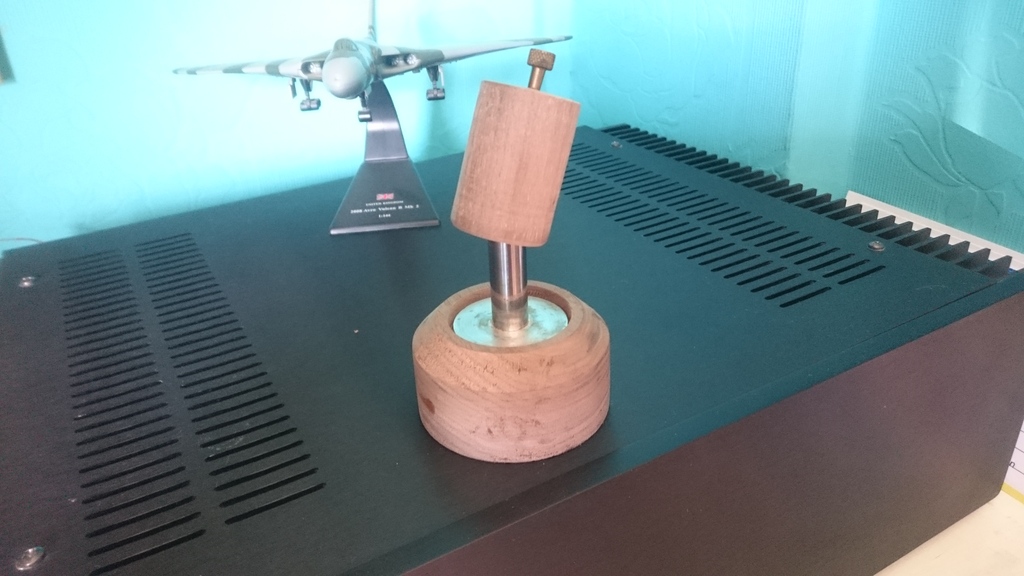

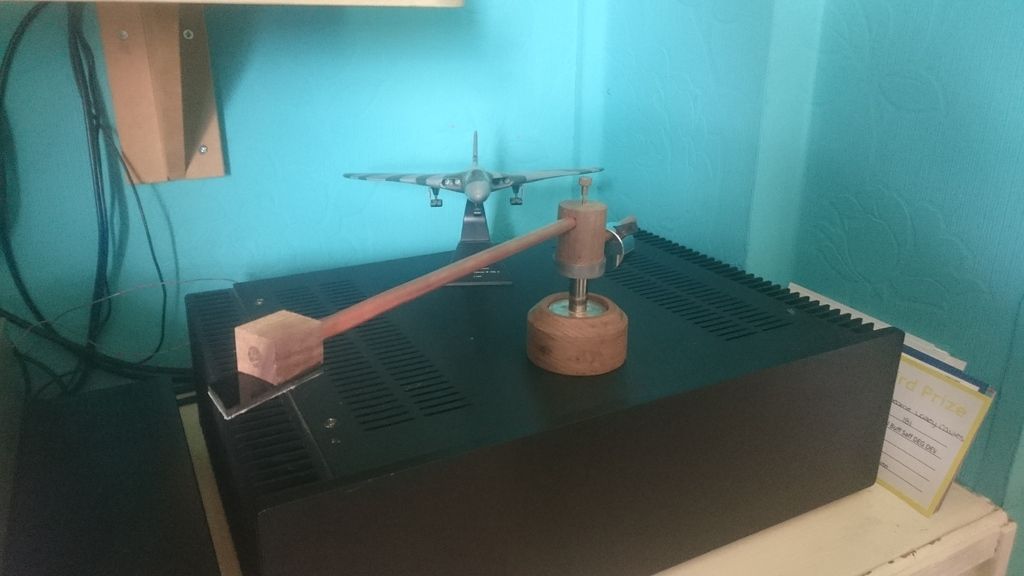

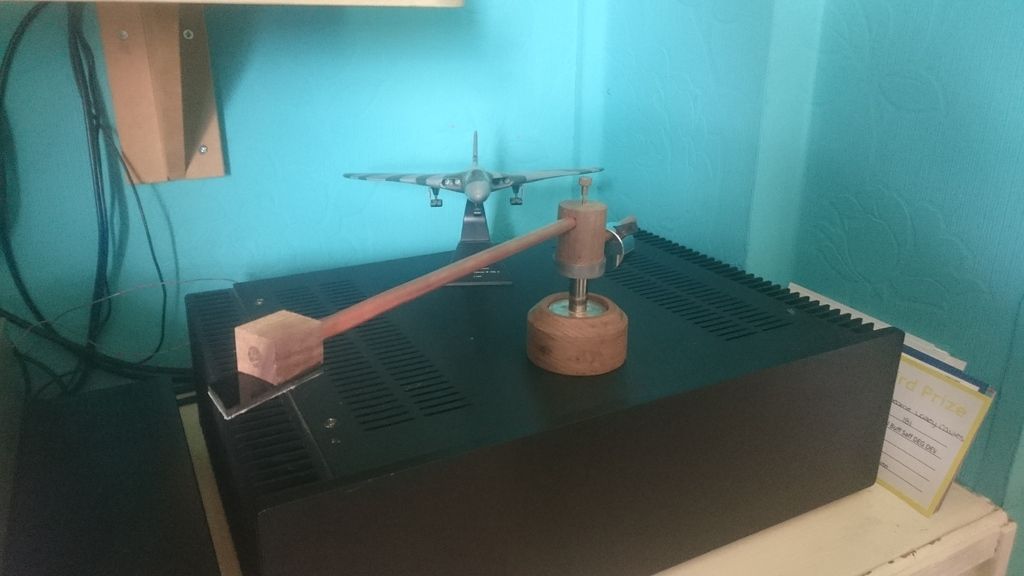

so with the machining finished and the piece parted off, here it is with the pin installed

and dropped on top of the bearing cup/ arm pillar

there is enough wood left between the top surface and the underside of the interior cutout to drill straight through for an arm wand depending on what i chose to do, im not sure at this point wether to go for a tube as i have some 8mm copper tube that is used for gas lines in gas fitting, or a flat walnut wand. i like the flat wand, i had good results with a flat tapered perspex one before

and dropped on top of the bearing cup/ arm pillar

there is enough wood left between the top surface and the underside of the interior cutout to drill straight through for an arm wand depending on what i chose to do, im not sure at this point wether to go for a tube as i have some 8mm copper tube that is used for gas lines in gas fitting, or a flat walnut wand. i like the flat wand, i had good results with a flat tapered perspex one before

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#19 Re: A unipivot made from scrap

And a base turned for the pillar. Might make this again, depends on how much clearance there is between the underside of the bearing housing and the bottom of the rebate in the top face

In use the bearing housing would drop below the top face of the base when the pillar is adjusted to the correct height

In use the bearing housing would drop below the top face of the base when the pillar is adjusted to the correct height

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#20 Re: A unipivot made from scrap

Now have a copper 8mm tube for an arm wand and stub.

The counterweight stub centre is 2mm below the pivot point and the counterweight rotated anti clockwise to set the lateral balance.

The ring below the stub around the housing is lead to add mass below the pivot point for stability, and keeps the mass centrailsed just under the pivot.

I chose a copper tube rather than a walnut wand as I had hum problems with the almostarega arm with unshielded cabling and I can do without hum chasing.

The tube goes all the way through the housing so the cable will exit out the back. The pin then goes through the tube to secure it.

That way, removing the pin frees the tube so i can play with different lengths

The counterweight stub centre is 2mm below the pivot point and the counterweight rotated anti clockwise to set the lateral balance.

The ring below the stub around the housing is lead to add mass below the pivot point for stability, and keeps the mass centrailsed just under the pivot.

I chose a copper tube rather than a walnut wand as I had hum problems with the almostarega arm with unshielded cabling and I can do without hum chasing.

The tube goes all the way through the housing so the cable will exit out the back. The pin then goes through the tube to secure it.

That way, removing the pin frees the tube so i can play with different lengths

-

simon

- Thermionic Monk Status

- Posts: 5647

- Joined: Thu May 24, 2007 11:22 am

- Location: People's Republic of South Yorkshire

#21 Re: A unipivot made from scrap

Impressive ant.

I get the hum thing, but I wonder how good copper will be? Might be great for all I know but I just wonder if it might be a bit soft? Probably just fine if used with care. Could be a bit resonant perhaps? But I'm basing that on nothing! Looking forward to the road test report.

I get the hum thing, but I wonder how good copper will be? Might be great for all I know but I just wonder if it might be a bit soft? Probably just fine if used with care. Could be a bit resonant perhaps? But I'm basing that on nothing! Looking forward to the road test report.

- Paul Barker

- Social Sevices have been notified

- Posts: 8989

- Joined: Mon May 21, 2007 9:42 pm

#22 Re: A unipivot made from scrap

nice job so far

"Two things are infinite, the universe and human stupidity, and I am not yet completely sure about the universe." – Albert Einstein

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#23 Re: A unipivot made from scrap

The copper tube is just what I had available hence the scrap, I have my eye on some 8mm stainless and some ally tubing aswell.

As its a lash up of sorts, i expect to be chopping and changing parts. When i was looking at sheilding the lenco motor in alis deck I was looking at different materials and copper was marginally better in terms of shielding than aluminium so maybe theres a plus there.

I reckon that drilling into the tube as I did with the rega will break up ringing in it if there is some (which i expect there will be, to what extent I dont know yet), this time around i can add silicone fluid to the bearing cup too, so there are a load of variables to play with

Still need to decide on a length yet as it needs to fit on the lenco in some way. So lots to do

As its a lash up of sorts, i expect to be chopping and changing parts. When i was looking at sheilding the lenco motor in alis deck I was looking at different materials and copper was marginally better in terms of shielding than aluminium so maybe theres a plus there.

I reckon that drilling into the tube as I did with the rega will break up ringing in it if there is some (which i expect there will be, to what extent I dont know yet), this time around i can add silicone fluid to the bearing cup too, so there are a load of variables to play with

Still need to decide on a length yet as it needs to fit on the lenco in some way. So lots to do

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#24 Re: A unipivot made from scrap

Decided to go with rega geometry for this iteration as it will make it simpler to test without buggering about with the lenco, the arm post will drop onto the existing arm board

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#25 Re: A unipivot made from scrap

Ok, next phase, how to attach a cart.

So here we have a headshell. Its made of another block of walnut with a black perspex 'deck' epoxied onto the underside.

The front edge is cut to 23 degrees, and rather than slots in it, there will be 2 holes for bolts like an aro, but unlike that arm, the idea is that the entire headshell will slide backwards along the tube so that the correct offset angle is maintained, and the effective length is the adjustable perameter as per slots. Doing it this way I can maintain the angle, i mean how many times do we look on ebay at a turntable, see a pic of the cart and immediately see that the cart is skewed in the headshell in a manner that means it was a mile out.

The headshell looks big, heavy and clunky but only weighs 6.25g, about 4 g lighter than most of the headshells I have for other arms

I'll leave the epoxy to cure before drilling the holes in it, and more on to the next bit, needs an arm rest.....

So here we have a headshell. Its made of another block of walnut with a black perspex 'deck' epoxied onto the underside.

The front edge is cut to 23 degrees, and rather than slots in it, there will be 2 holes for bolts like an aro, but unlike that arm, the idea is that the entire headshell will slide backwards along the tube so that the correct offset angle is maintained, and the effective length is the adjustable perameter as per slots. Doing it this way I can maintain the angle, i mean how many times do we look on ebay at a turntable, see a pic of the cart and immediately see that the cart is skewed in the headshell in a manner that means it was a mile out.

The headshell looks big, heavy and clunky but only weighs 6.25g, about 4 g lighter than most of the headshells I have for other arms

I'll leave the epoxy to cure before drilling the holes in it, and more on to the next bit, needs an arm rest.....

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#26 Re: A unipivot made from scrap

Looking at it, from an aesthetic point of view I would have preferred the walnut block part of the headshell to be circular, however the tools i have are geared towards bigger things which makes it more difficult to make smaller parts as accurately as I would like.

Id love a small lathe with a mill drill atrachment for stuff like this, like the emco unimat or a hobbymat md65. Tbh i would love to have the hobbymat to complement the al ko hdm 850 I have, as the al ko is based on on the md65 as it is, and the quality is great

Id love a small lathe with a mill drill atrachment for stuff like this, like the emco unimat or a hobbymat md65. Tbh i would love to have the hobbymat to complement the al ko hdm 850 I have, as the al ko is based on on the md65 as it is, and the quality is great

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#27 Re: A unipivot made from scrap

Got the arm rest base made, think simple again, dont over complicate.

Anothe bit of walnut with a hole for the pillar and an m5 grub screw so secure it. There is a couple of lenco arm rests knocking about somewhere so i'll use one of them when I can find one

Ive blu taked a cart on to see what effect it has on the lateral balance, not much, ive kept the mount along the centre line.

You can see that the stylus is almost 3/4" lower than the arm tube, pretty much in line with where the pivot is inside the housing (actually 16mm lower now ive measured it)

The arm will be at least an inch shorter than it is at the moment, need to work out by how much

Anothe bit of walnut with a hole for the pillar and an m5 grub screw so secure it. There is a couple of lenco arm rests knocking about somewhere so i'll use one of them when I can find one

Ive blu taked a cart on to see what effect it has on the lateral balance, not much, ive kept the mount along the centre line.

You can see that the stylus is almost 3/4" lower than the arm tube, pretty much in line with where the pivot is inside the housing (actually 16mm lower now ive measured it)

The arm will be at least an inch shorter than it is at the moment, need to work out by how much

- IslandPink

- Amstrad Tower of Power

- Posts: 10041

- Joined: Tue May 29, 2007 7:01 pm

- Location: Denbigh, N.Wales

#28 Re: A unipivot made from scrap

There's no stopping you !

Do you have a nice can of Danish oil waiting in the wings ? This is what Schroeder uses to make the wood much more dead - hence neutral. Several applications are required to get it to soak right into the wood.

Do you have a nice can of Danish oil waiting in the wings ? This is what Schroeder uses to make the wood much more dead - hence neutral. Several applications are required to get it to soak right into the wood.

"Once you find out ... the Circumstances ; then you can go out"

- cressy

- Shed dweller

- Posts: 2906

- Joined: Fri Aug 03, 2007 7:07 pm

- Location: the great white space

- Contact:

#30 Re: A unipivot made from scrap

All the wooden bits bar the base ( need to re make that as its too big have gone in a cup full of Danish oil to soak for a couple of hours.

I'll pull them out later and leave them to dry.

How the epoxy on the headshell will react is anyones guess. Plenty of materials to make another though

I'll pull them out later and leave them to dry.

How the epoxy on the headshell will react is anyones guess. Plenty of materials to make another though